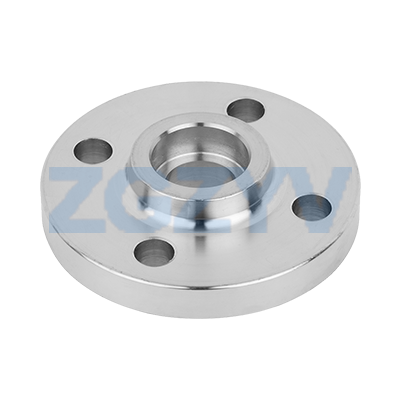

How to repair cracks on the flange?

Cracks in flanges can be repaired through various methods. Before processing, the length, depth, and distribution range of the cracks should be checked and analyzed comprehensively.

Minor surface cracks can be temporarily sealed and reinforced. Apply high-temperature resistant polymer composite materials (such as epoxy resin composite agents) to fill gaps, and wrap and fix them with metal bandages to temporarily restore sealing. But if the crack length exceeds 10% of the flange diameter or a penetrating crack appears, it is necessary to immediately stop the operation and release the pressure to avoid accidents caused by medium leakage.

Temporary handling is only applicable in emergency situations, and the actual problem of cracking needs to be repaired through professional methods.

1. Surface crack repair

Mechanical polishing: Use an angle grinder to remove the surface metal of the crack until the complete base material is exposed.

Welding repair: TIG welding is used to repair the corrosion-resistant alloy layer (such as 316L stainless steel), and after welding, it is ground to the original sealing surface accuracy.

2. Deep crack treatment

Cut off the damaged area: Cut off 5mm of metal on both sides along the direction of crack propagation, thoroughly removing the stress concentration area.

Repair welding and heat treatment: Segmented welding and control of interlayer temperature (≤ 150 ℃), followed by stress relief annealing (600 ℃ insulation for 2 hours with slow cooling) after welding.

After the crack repair is completed, the welding area needs to undergo penetration testing and hardness testing (HB ≤ 220) to ensure that there are no new defects.、