Forged steel filters specialize in treating the “king of destruction” in pipelines!

Forged steel filters are used to intercept destructive molecules such as welding slag and rust, protecting valves and water pumps from being attacked by “hidden weapons”.

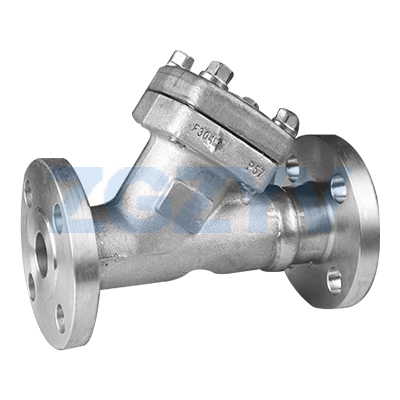

It consists of a forged steel shell, a filter basket/screen, and a drain outlet. The forged steel shell is integrally formed by high-pressure forging and can withstand a pressure of 40MPa; A filter basket/screen is a perforated stainless steel mesh used to screen out impurities; The sewage outlet can regularly open the valve to flush away garbage without dismantling or washing.

This forged steel filter is specifically designed to treat the “king of destruction” in pipelines:

Welding slag or iron shavings can block the valve, scratch the sealing ring, trap the filter mesh, and flush away the drain outlet; Scale or crystallization can clog precision instruments, and the filter basket of the filter can trap and be disassembled, washed, and reused; Rust blocks in the pipeline can damage the impeller of the water pump, and the steel shell of the forged steel filter is hard to bear, while the filter screen is buffered.

The forged steel filter is the bulletproof vest in the pipeline industry. Its forged steel shell can withstand high pressure, and the filter screen acts as a shield to block impurities. It is specially designed for high-risk scenarios such as oil fields, chemical plants, and power stations.