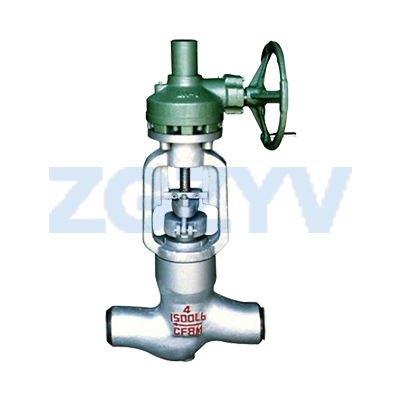

These faults are very common on stainless steel globe valves!

Stainless steel globe valves are generally durable, but if used in harsh environments, maintained or installed improperly, they are also prone to a series of failure risks.

The common faults mainly focus on these aspects:

1. Sealing surface damage (over 60% of faults are caused by this)

Impurity blockage: Welding slag and particulate matter are embedded in the gap between the valve disc and seat, causing poor closure or scratching of the sealing surface (filter installation is required to prevent this).

Medium erosion: Long term erosion by steam containing droplets or high-speed fluids can form grooves on the sealing surface (it is recommended to use Stellite alloy sealing surface).

Chemical corrosion: Strong acid/alkali media corrode sealing materials (corrosion-resistant materials such as 316L should be selected according to the characteristics of the medium).

2. Leakage of valve stem and packing box

Frequent opening and closing: accelerates the wear of the packing, causing external leakage (the gland bolts need to be adjusted every quarter).

Installation tilt: Failure to install the valve stem vertically can result in eccentric wear (50% reduction in lifespan when deviation>3 °).

3. Structural damage to valve body

Casting defects: sand holes or cracks expand under high pressure (radiographic testing is required for pressure>6.4MPa).

Low temperature brittle fracture: Special low-temperature steel should be selected below -29 ℃.

In fact, there is no need to worry excessively. As long as the installation is standardized (vertical valve stem+downstream direction) and regular maintenance (cleaning+sealing test) is carried out, genuine stainless steel globe valves can be used with confidence for 8-10 years! If there are many environmental impurities, extreme temperatures, or high-frequency opening and closing, the failure rate will significantly increase.