Introduction to common structural forms of forged steel filters

The structural form of forged steel filters mainly revolves around the layout of filter elements, medium flow paths, and installation and maintenance convenience design. Different structures correspond to different working conditions requirements (such as medium pressure, flow rate, impurity content, and whether shutdown maintenance is allowed). The core is to ensure the high strength and high pressure resistance advantages of forged steel materials while achieving efficient filtration and convenient operation and maintenance.

Among them, the basket structure is a relatively basic and commonly used type, with a forged steel integrated shell and a detachable basket shaped filter screen (usually made of stainless steel, with mesh holes selected according to filtration accuracy) inside. After the medium enters from the inlet of the shell, it will flow through the filter screen along the cavity, and impurities will be trapped inside the filter screen. The filtered clean medium will enter the outlet end through the gap of the filter screen. The advantage of this structure is that the filter screen is easy to remove. During maintenance, only the top or side end caps need to be opened, and the filter screen can be directly removed, cleaned or replaced without dismantling the entire connection between the filter and the pipeline. It is particularly suitable for scenarios where there are many impurities in the medium and frequent cleaning is required. Due to the large cavity space, it can accommodate more impurities and reduce cleaning frequency. It is commonly used for filtering low to medium pressure media such as oil and water.

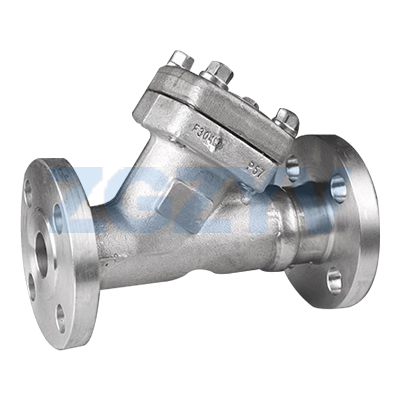

The Y-shaped structure is named after the overall “Y” shape of the shell, and its design is more suitable for the installation of branch or straight pipe sections in pipeline systems, without requiring additional space occupation. The medium enters from one port of the “Y” shape, passes through a built-in cylindrical filter screen (the axis of the filter screen is at a certain angle to the flow direction of the medium), and flows out from the other port, with impurities settling on the side of the filter screen facing the incoming medium. The characteristic of this structure is flexible installation, which can be installed horizontally or vertically (when installing vertically, attention should be paid to the flow direction of the medium to ensure that impurities can deposit smoothly), and the volume is relatively compact, suitable for pipeline systems with limited space and medium flow rate, such as hydraulic systems and pre filtration of compressed air pipelines. However, due to the small space for impurities in the filter screen, it is more suitable for media with less impurity content. During maintenance, the end cover needs to be removed to remove the filter screen. Some high-pressure models are designed with quick opening structures to shorten maintenance time.

The T-shaped structure (also known as the three-way structure) focuses more on high-pressure and high flow scenarios. Its shell is a forged steel three-way shape, with two ports for medium inlet and outlet, and a third port (usually the side or top end) for installing and removing the filter screen. The filter screen is mostly cylindrical and placed vertically or horizontally inside the shell cavity. After entering from one end, the medium needs to pass through the entire circumference of the filter screen before flowing out from the other end. This flow path allows the medium to fully contact the filter screen, resulting in high filtration efficiency. Moreover, the wall thickness design of the forged steel shell can withstand higher pressure (commonly seen in high pressure conditions of PN16 and above), making it suitable for filtering media such as natural gas, high pressure steam, and high pressure oil products. However, the maintenance of T-shaped structures is relatively complex, usually requiring cutting off the medium flow first, and then disassembling the flange or end cover at the installation end of the filter screen. Therefore, it is more suitable for harsh working conditions with less impurities and longer maintenance cycles.

In addition, there is a dual structure (consisting of two independent basket or Y-shaped filters connected in parallel), which is designed for systems that do not allow shutdown. The two filters can be used alternately – when the filter screen of one filter needs to be cleaned, the valve is switched to allow the medium to flow through the other filter, achieving non-stop maintenance. It is common in continuous production chemical and petrochemical plants, but its structure is relatively complex, and its volume and cost are also higher.

The design of these structural forms is essentially based on the mechanical properties of forged steel materials (high pressure resistance, impact resistance), optimized for different installation spaces, medium characteristics, and operation and maintenance needs. When selecting, it is necessary to comprehensively consider the pressure, flow rate, impurity type and content of the medium, as well as whether the system allows shutdown maintenance and other factors, to ensure that the filter can filter efficiently and adapt to the operational requirements of the overall pipeline system.